All about Our Webinar! Computer Vision - Brains behind Workplace Safety & Employee Productivity

Written by Team Wobot

Table of Contents

Introduction

Granted, it’s been a while but now we’re back with some valuable insights from our recent webinar “Computer Vision – Brains behind Workplace Safety & Employee Productivity.” In the following, we’ll be exploring the key aspects of computer vision and the various pain points related to workplace safety and employee productivity both in the manufacturing and food processing industries.

But before we delve into the dynamics of these industries, let’s learn the fundamentals of computer vision and their various compliances.

What is computer vision?

As indicated in the webinar, computer vision is a field of artificial intelligence that allows computers and systems to derive meaningful data from digital images and videos. Based on these data insights, one can take corrective actions.

The computer vision algorithms that we observe and use today are based on pattern recognition. Computers are trained to gather large amounts of visual information which includes processing images, labeling the objects on them, and finding patterns in those objects.

The various tasks that a computer vision system can be used for are explained in the following:

Object classification

This is a task that determines which objects are present in an image or video. It refers to the training of machine learning models to find out which classes (objects) are present by putting them into categories.

Object identification

This refers to the object being placed into further categories.

Object tracking

This means the computer vision system analyzes that video or image and tracks the activity.

How does computer vision help with workplace safety?

According to a 2019 survey by EHS Daily Advisor, 55% of companies said that "workers generally wear PPE when required - but sometimes need to be reminded." And while those numbers might come as a surprise to many, listed below are some of the solutions that computer vision can provide: -

**Solutions **

- Computer vision in the manufacturing industry can easily facilitate workplace safety as they can quickly analyze data at a rate that’s difficult for humans to achieve

- With meaningful data insights, your computer vision model can easily recognize patterns that will help ensure better employee safety

- Personal protective equipment (PPE) is safety gear that serves as protective layers where risky tasks are known to happen

- PPE includes headgear, safety vests, and eyewear that will minimize the frequency and severity of workplace accidents

To ensure all-around safety and productivity adherence by employees, the webinar speaks at length, about how computer vision has laid out various SOPs and industry best practices. These are known as checklists and each of these checklists contains a series of tasks.

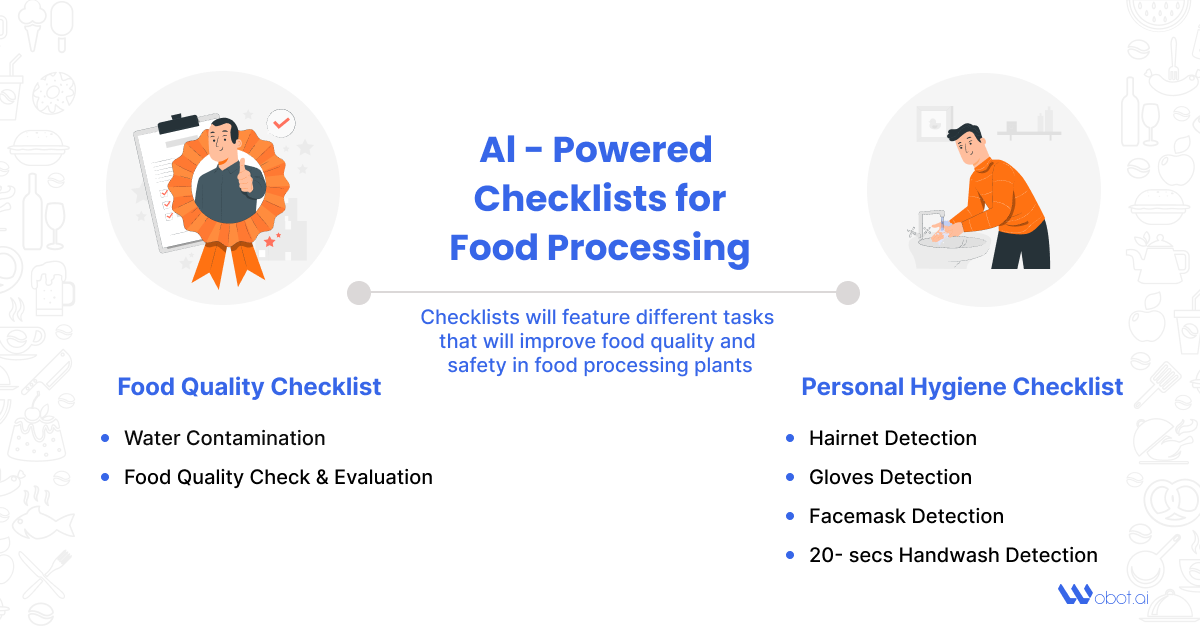

AI Powered Checklist for Food Processing

- Food Quality Checklist

- Water Contamination

- Food Quality Check & Evaluation

- Personal Hygiene Checklist

- Hairnet Detection

- Gloves Detection

- Facemask Detection

- 20- secs Handwash Detection

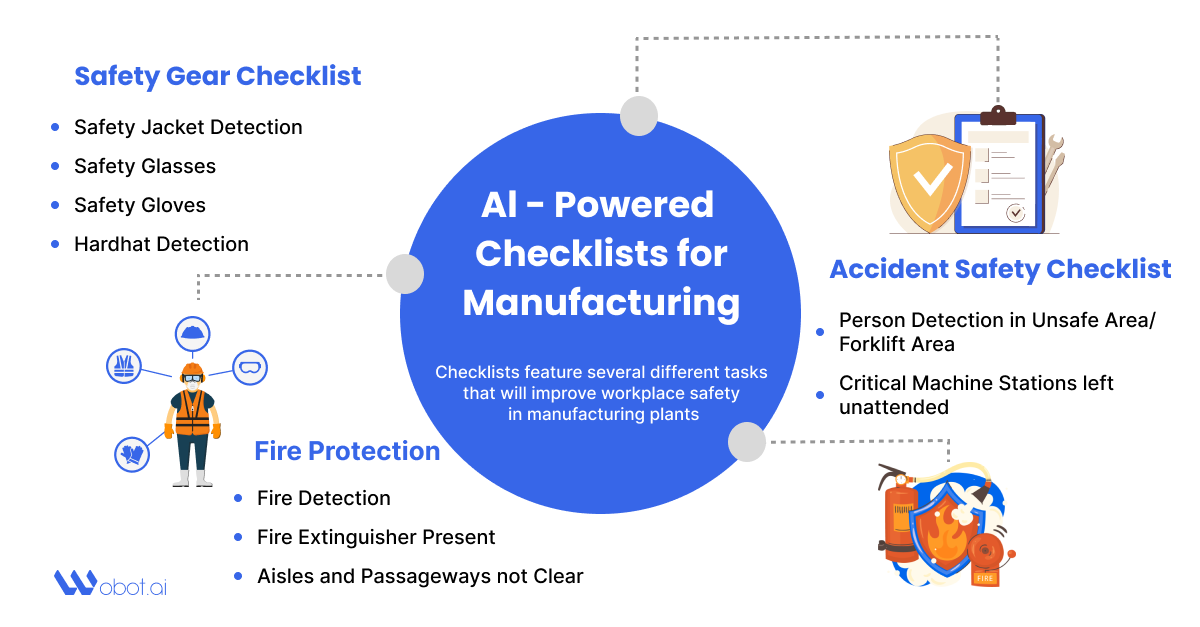

AI Powered Checklist for Manufacturing

- Accident Safety Checklist

- Person Detection in Unsafe Area/Forklift Area

- Critical Machine Stations left unattended

- Safety Gear Checklist

- Safety Jacket Detection

- Safety Glasses

- Safety Gloves

- Hardhat Detection

- Fire Protection

- Fire Detection

- Fire Extinguisher Present

- Aisles and Passageways not Clear

How can Wobot.ai help?

Manufacturing and food processing facilities can leverage AI–enabled checklists to keep track of adherence to standard operating procedures (SOPs). With a robust video intelligence platform, your facility can send real-time alerts to managers if one or more of the tasks designated on checklists are shown to have deviated from the prescribed norms.

Learn to identify, analyze and mitigate process deviations in real-time with video intelligence.

P.S. You’re signing up for value here. No spam. No overly promotional emails.

Table of Contents

Related Blogs

See All